Vintage drystack is now history

Technology has been promoted to saturation point with regard to drystack automation. Some 15 years ago, the concept then known as Vertical Yachts was received with awe by prospective clients acquiring a condo + boat in Fort Lauderdale. But the system, and those that followed, did not captivate the users as expected. Oscar Siches reports

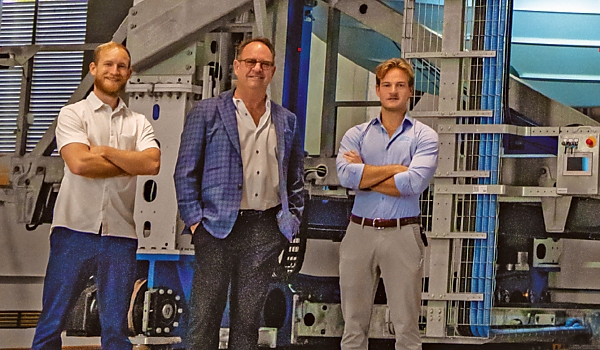

ASAR founder and CEO Robert Brown (centre) with his sons Max Brown (left), vice president, and David Brown (right), business development, inside the Gulf Star Marina drystack building.

GCM from Fort Myers, the builder of this drystack, used the tilt-up technique: slabs for every wall, cell and level are created flat on the ground and afterwards lifted into position by crane and fixed together. This technique avoids the need to completely surround the building with scaffolding and requires just a small ground surface area for the work set-up. As Hamilton Harbour proved to be a successful operation, GCM realised that with an automated crane to move the boats, the centre aisle width (needed for forklift manoeuvring) could be significantly narrower, reducing the footprint of the building and either reducing the cost of the plot or freeing land up for commercial and hospitality use.

GCM owner, Robert Brown, went hunting for what he considered to be the ideal machinery (crane) to handle the boats. After finding and discarding existing maritime equipment, he found LTW, an Austrian manufacturer of all types of containers moving equipment in all temperatures, humidity and corrosion-prone conditions. Drystacks are usually at the shoreside, they are humid and suffer salty air from the sea. Most boaters are aware (more or less) of this exposure. But let’s consider a few other aspects that are not so obvious.

Gulf Star, the pioneering ASAR marina, has generous add-on space for a popular restaurant.

But typical drystacks had a few downsides. They were ugly sheds spoiling the natural beauty of a shoreside. Most of them were run by forklifts, generating loud noise from their engines and hydraulics, and dripping the inevitable lube and hydraulic oil in the aisle and launching/lifting platform. The exhaust gases (not called emissions then) were there, but we were not conscious of the damage being done. In a way, the 1960s ended the old-style industrial revolution; bigger, taller and more powerful was still better – and nothing to worry about.

I apologise if I am distracting you with tales from the past, but I truly believe history has always influenced modern issues. History helps us to be better prepared to understand and deal with the present! And that’s what Robert Brown did. He visited old facilities, talked to operators, witnessed operations, and conceived ideas for his new, super-efficient drystack. A few years later, he found an old facility whose operator was willing to take a big step towards modernity, and the new Gulf Star ASAR drystack was born.

The tilt wall construction method was first used for Hamilton Harbour Yacht Club in 2008, saving space and time, and reducing the need for scaffolding.

The choice of LTW crane technology included an independent, electric propulsion cart to fetch and deliver the boats to their appointed place in the building instead of the fixed forks of forklifts and column lifts. As unimportant as it sounds, the cart system allows for fundamental advantages: it allows the storage of boats in line on each building slot, increasing capacity by 30% to 50% within the same footprint, and allows the storage of large boats at the highest levels, incrementing the occupation per surface rate for prime rate boats.

Efficiency comes hand in hand with safety and reduced running costs. We know that in the unfortunate case of a fire starting, heat sensors will trigger an array of inert foam generators and will fill the whole volume of the drystack in 10 to 15 minutes, depending on the facility size. Operators can now rest easier. They can also save energy as, due to the very low electricity consumption, the facility can be run on solar panels. It can also be partially built underground to respect local building codes.

The system can be fully automatic, semi-automatic or fully manual to allow for storage stages, including services (hull cleaning and washing, polishing and repairs). It also has a self-learning capability, creating each boat’s usage expectation, be that seasonal, all-year-round, or just weekends, and making the most efficient distribution of each boat in the slots accordingly. This is the same principle supermarkets use when bringing forward Christmas decorations, Thanksgiving turkey and dressings in October, or hearts and chocolates before Valentine’s. It is a priority-by-use protocol and very efficient in most cases. The most used, busiest boats get the prime position.

Drystack design concepts, as can be seen in this CGI, can be multi-use and incorporate extensive architectural detailing.

The shoreside not only provides visitors with pleasant, natural landscapes but also the opportunity to rent small watercraft (canoes, waterboards, etc). The magic lies in providing the local community as well as the boat users with a destination for enjoying the water; a community driven by its enjoyment of the facility.

And in larger drystacks the lower levels can form a condominium project. In this case, the absence of noise and emissions becomes even more important, and the possibilities of increasing the shoreside community services are almost limitless. A destination is born.

To wrap up, we have a system that is hurricane-proof, fire-resistant, silent and community-focused. It optimises use of space, can be powered by solar panels, be fully or semi automated or manually driven, has a very low CO2 footprint and a friendly visual impact. The modern automated drystack results from experience, user preferences, and ASAR’s forward vision and innovation.